Подъемники Launch с нижней синхронизацией

Suitable for all locations due to the lower synchronization (no ceiling height requirements) and the possibility of placing the rack with the power unit and control panel on either side (saving on power cable routing and ease of subsequent use). Reliability and durability Launch lifting devices have increased dimensions of the stand, support platform, as well as metal thickness of the stand profile - 6 mm for TLT240SBA model and 5 mm for ECO TLT240SB and TLT235SB (A) models. I...

Подробное описаниеВсе комплектации

| Стоимость | Наличие | Тоннаж | Высота | Управление стопорами |

|

|

3.5 | 2860 мм | Механическое | |

|

|

3.5 | 2860 мм | Механическое | |

|

|

4 | 2860 мм | Механическое | |

|

|

4 | 2860 мм | Механическое | |

|

|

3.5 | 2860 мм | Рычагом с одной колонны | |

|

|

4 | 2860 мм | Рычагом с одной колонны | |

|

|

3.5 | 2860 мм | Автоматизированное | |

|

|

3.5 | 2860 мм | Автоматизированное | |

|

|

4 | 2860 мм | Автоматизированное |

Преимущества и специальные предложения

Suitable for all locations due to the lower synchronization (no ceiling height requirements) and the possibility of placing the rack with the power unit and control panel on either side (saving on power cable routing and ease of subsequent use).

Reliability and durability

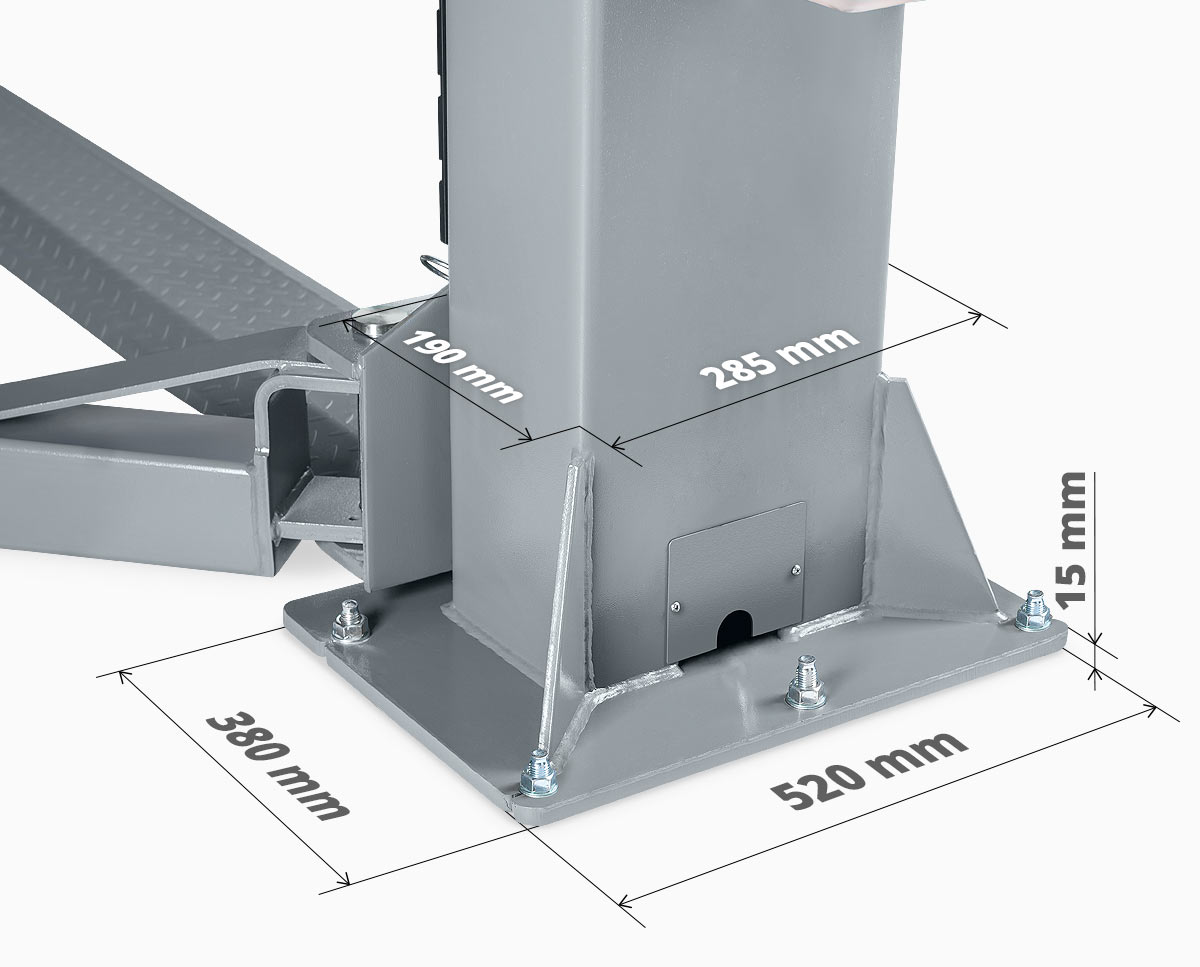

Launch lifting devices have increased dimensions of the stand, support platform, as well as metal thickness of the stand profile - 6 mm for TLT240SBA model and 5 mm for ECO TLT240SB and TLT235SB (A) models.

In terms of technical parameters, rigidity and strength of all elements and tested load according to European certification, Launch elevators with standardized lifting capacity of 3.5 tons surpass most Chinese elevators, whose lifting capacity is marked as 4 tons.

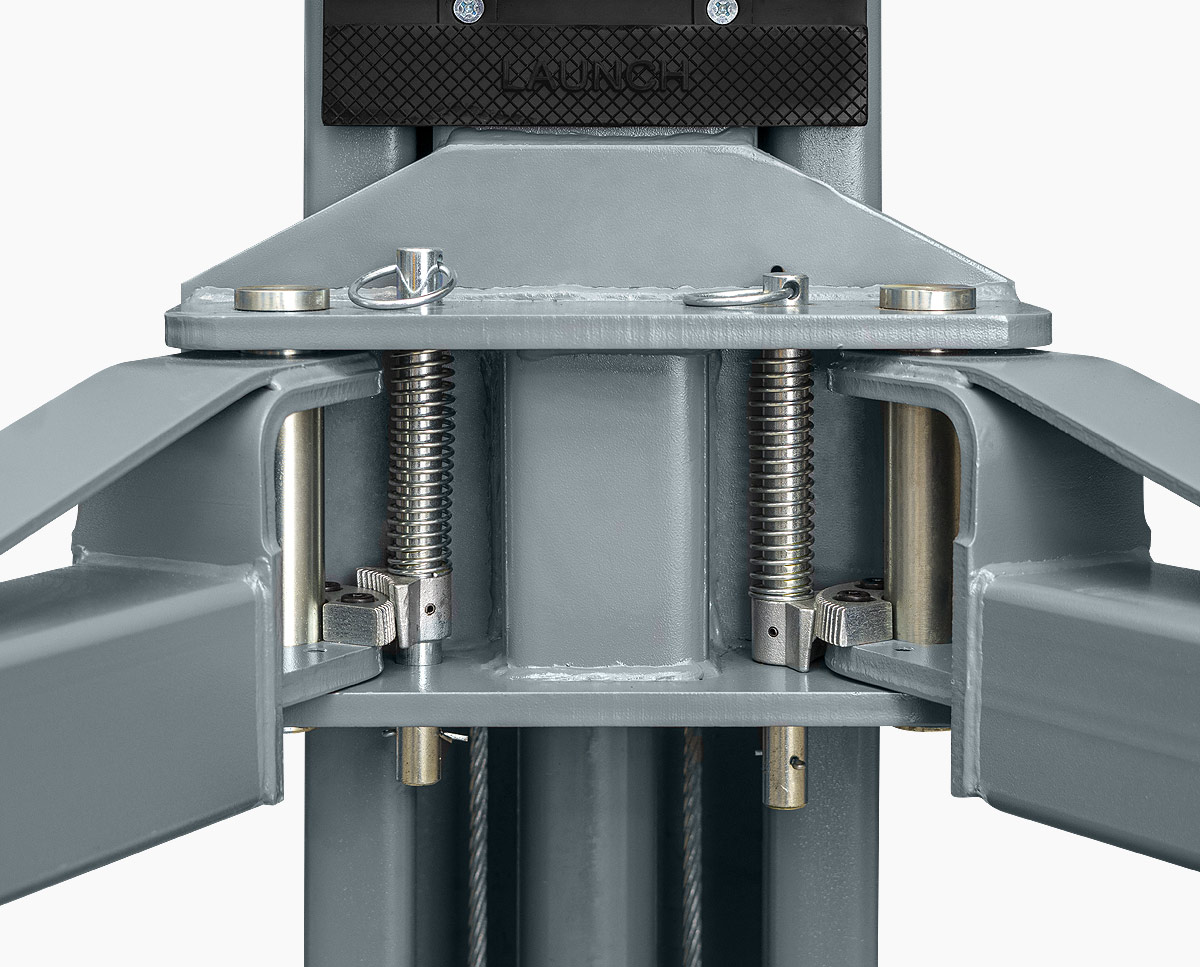

Reinforced struts and dimensions of the support platform ensure absolute rigidity of the Launch elevator and reduce the load on the foundation.

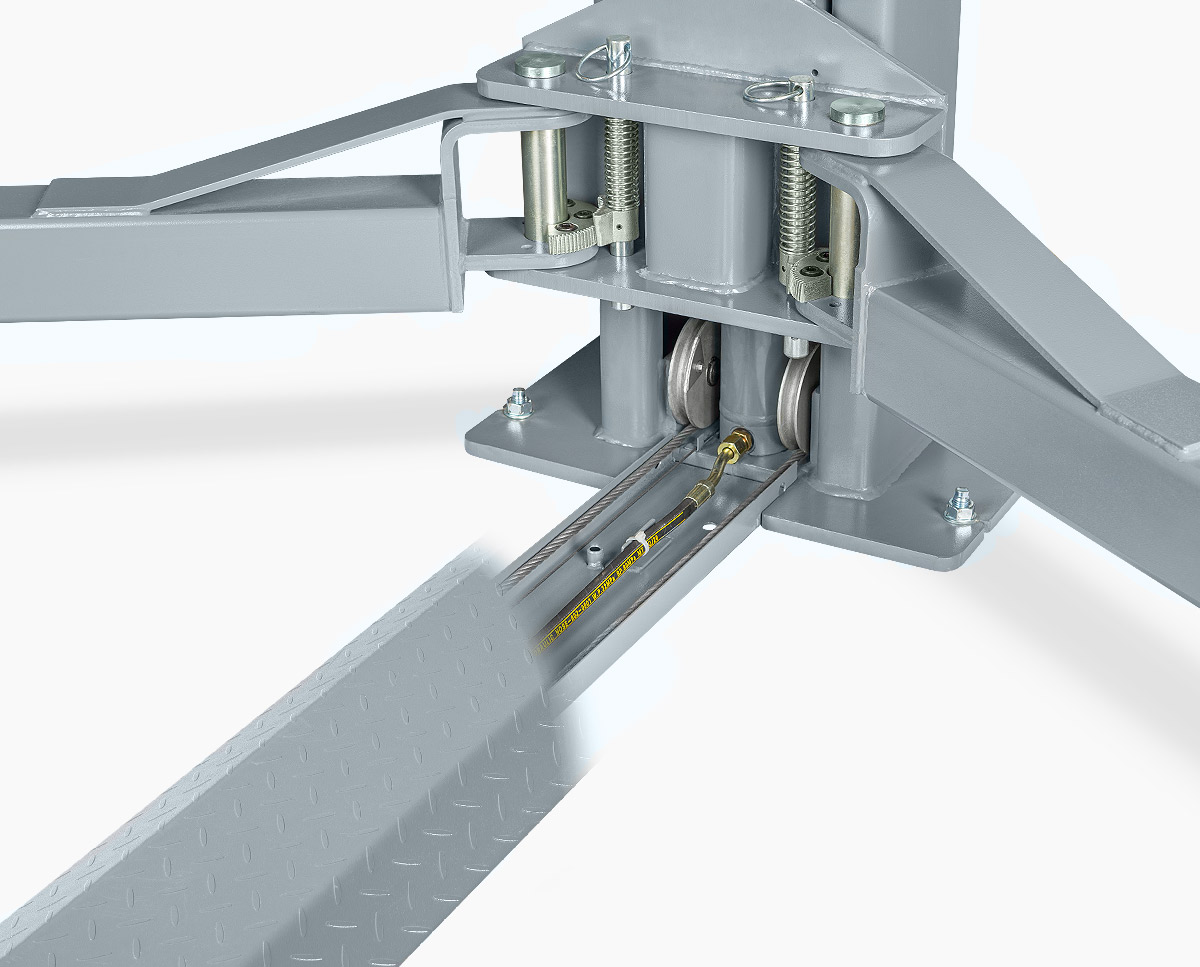

A double protective ladder between the props, consisting of an upper cover and a lower chute that fits closely into the grooves of the props' supports, thus protecting cables, hydraulic lines and electrical wiring from water and dirt - both from below and above.

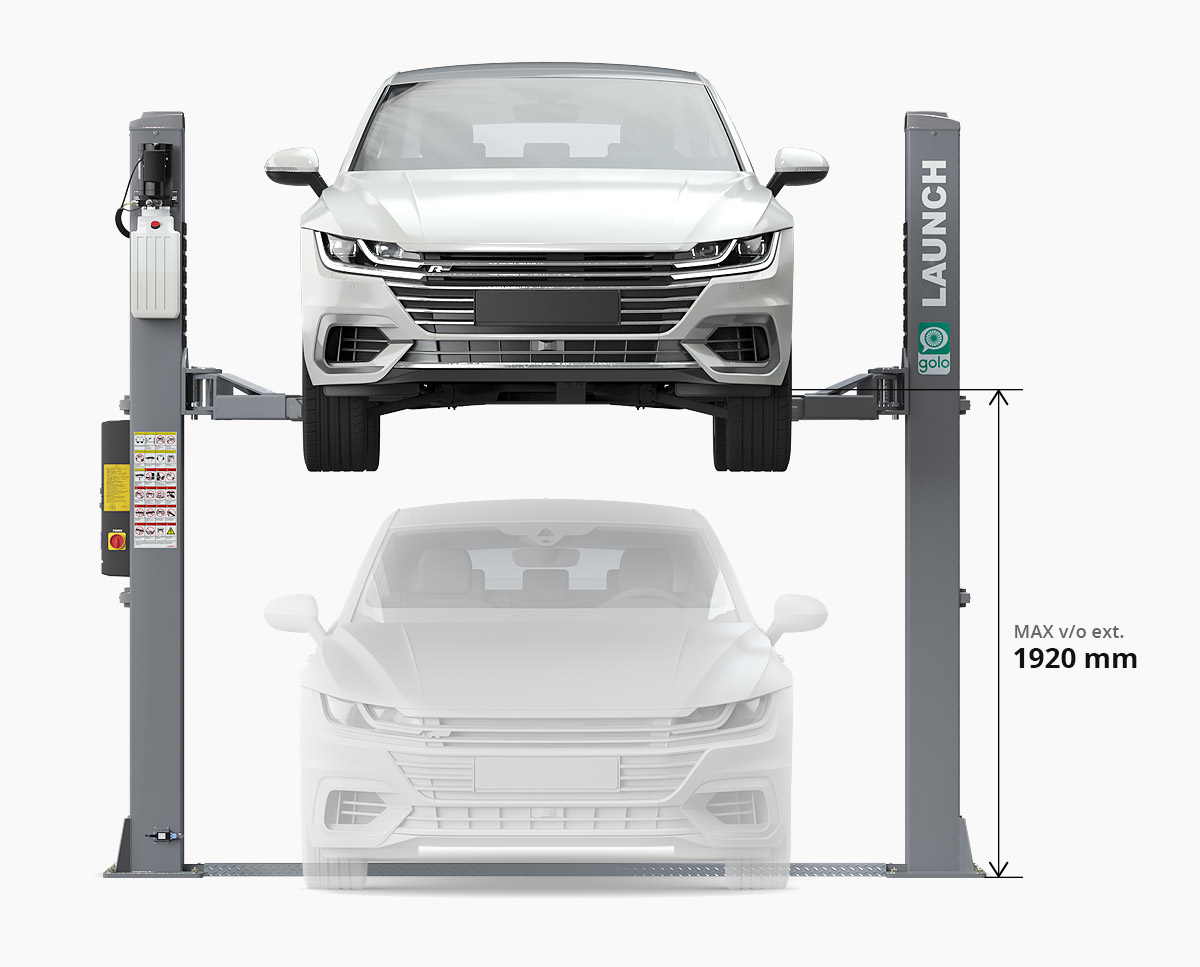

The increased lifting height of the vehicle - 1920 mm (without taking into account the spacers - extensions of the grip) - provides convenience for the craftsman when performing any tasks.

Increased tine thickness

Provides a stable fixation of the vehicle.

Protection and convenience for the craftsman

The elevator tines are equipped with safety frames to prevent the tine from dropping to its feet. (except ECO TLT240SB model)

The reinforced carriage profile distributes the load evenly and provides rigidity to the tine support system.

Convenient and safe operation

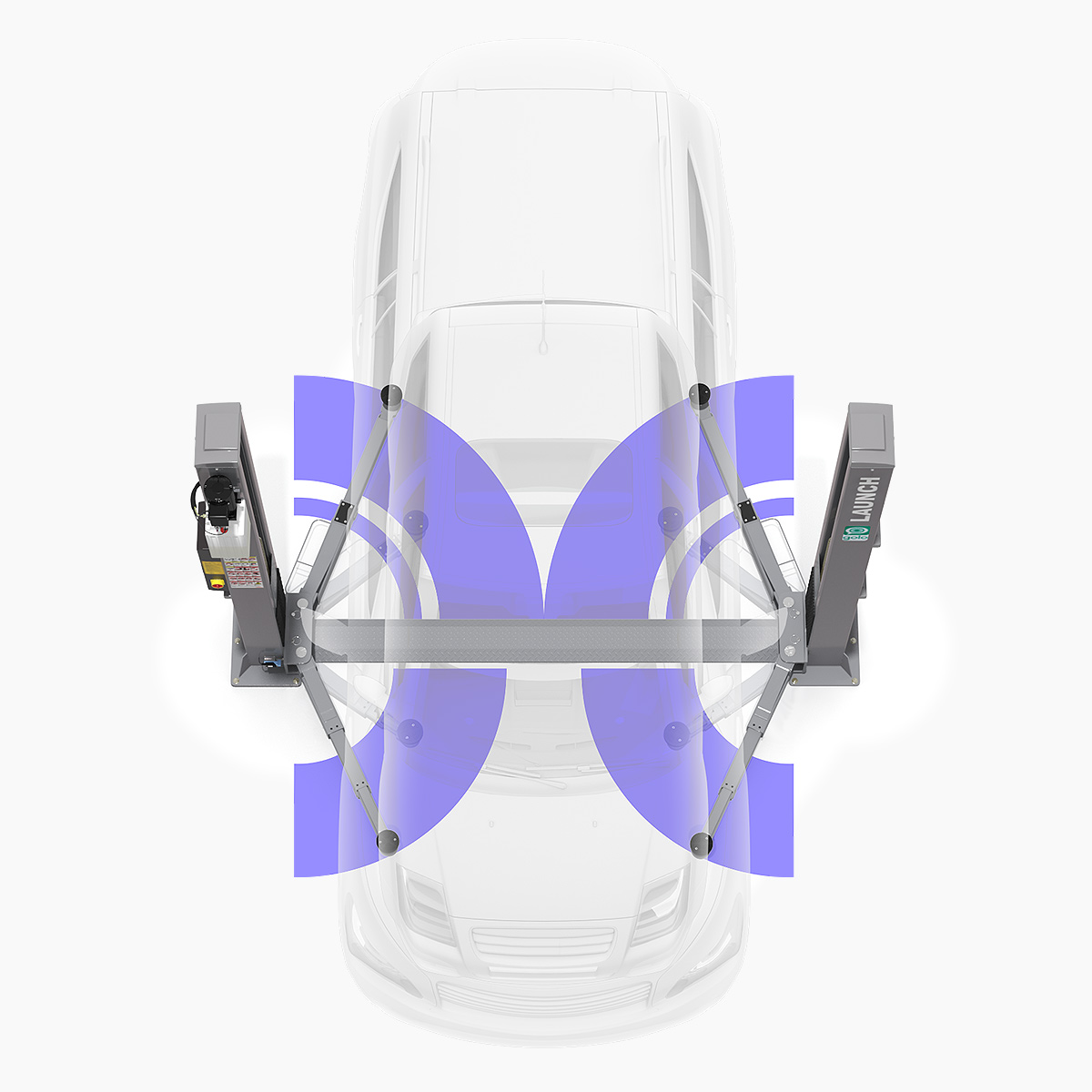

Launch elevators allow servicing all popular car configurations - from A-class small cars to vans (according to the tonnage and weight distribution of the car).

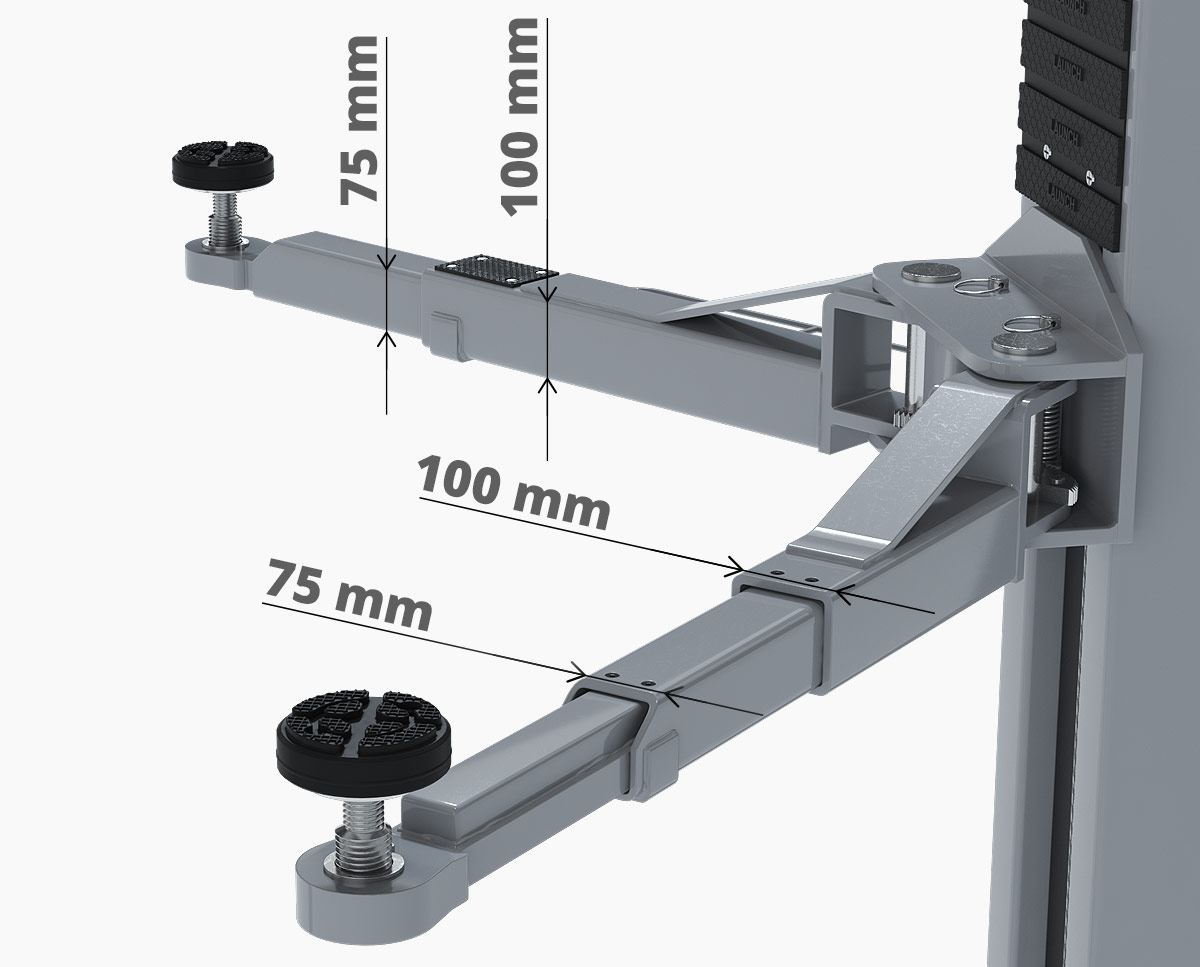

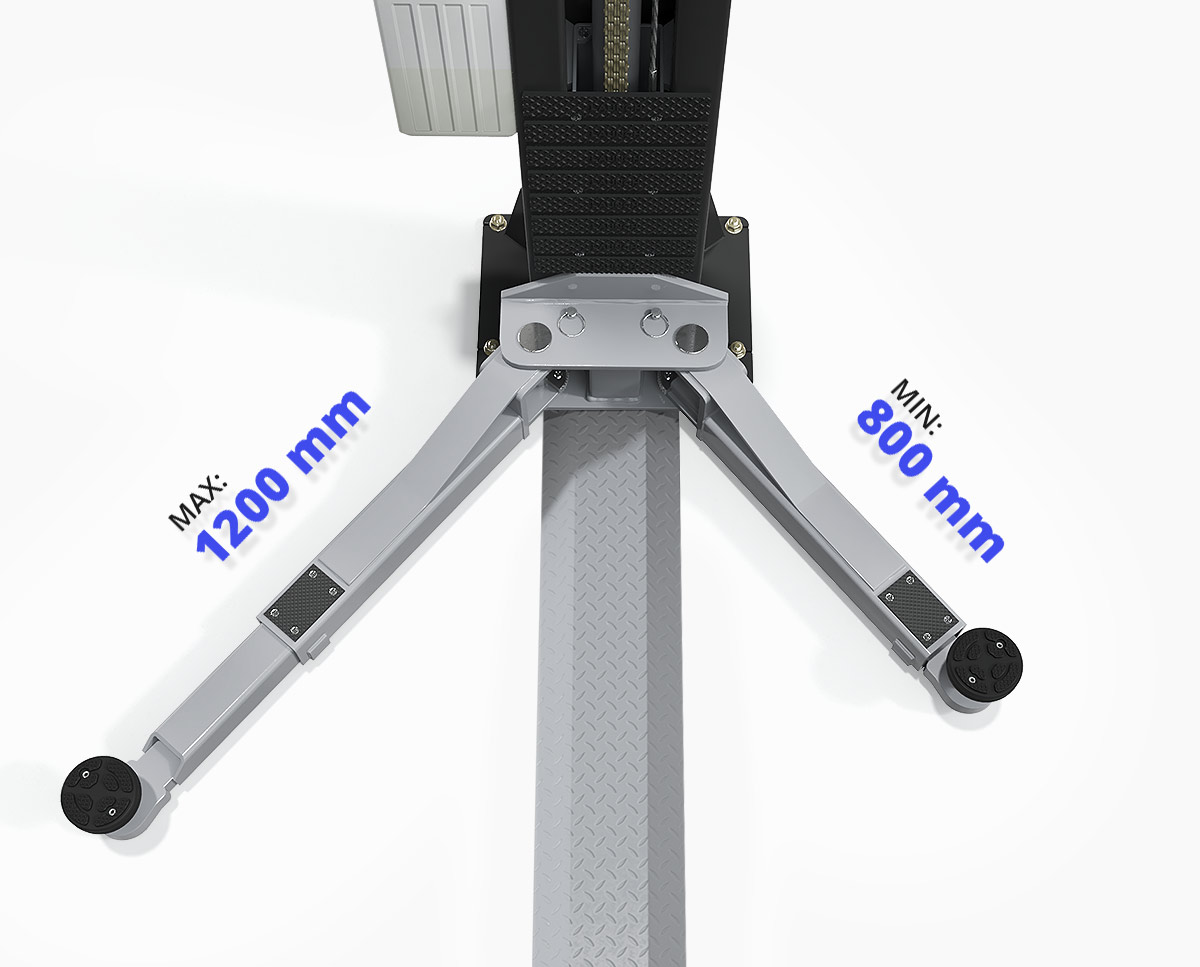

Default configuration: front pair is 2-section with a range of 800 -1200 mm.

Rubber covers on the carriages to protect the car doors - without sharp edges and over the entire height of the carriage. Optional metal cover to cover the moving parts of cylinders and chains and prevent dirt and foreign objects from entering the elevator mechanism.

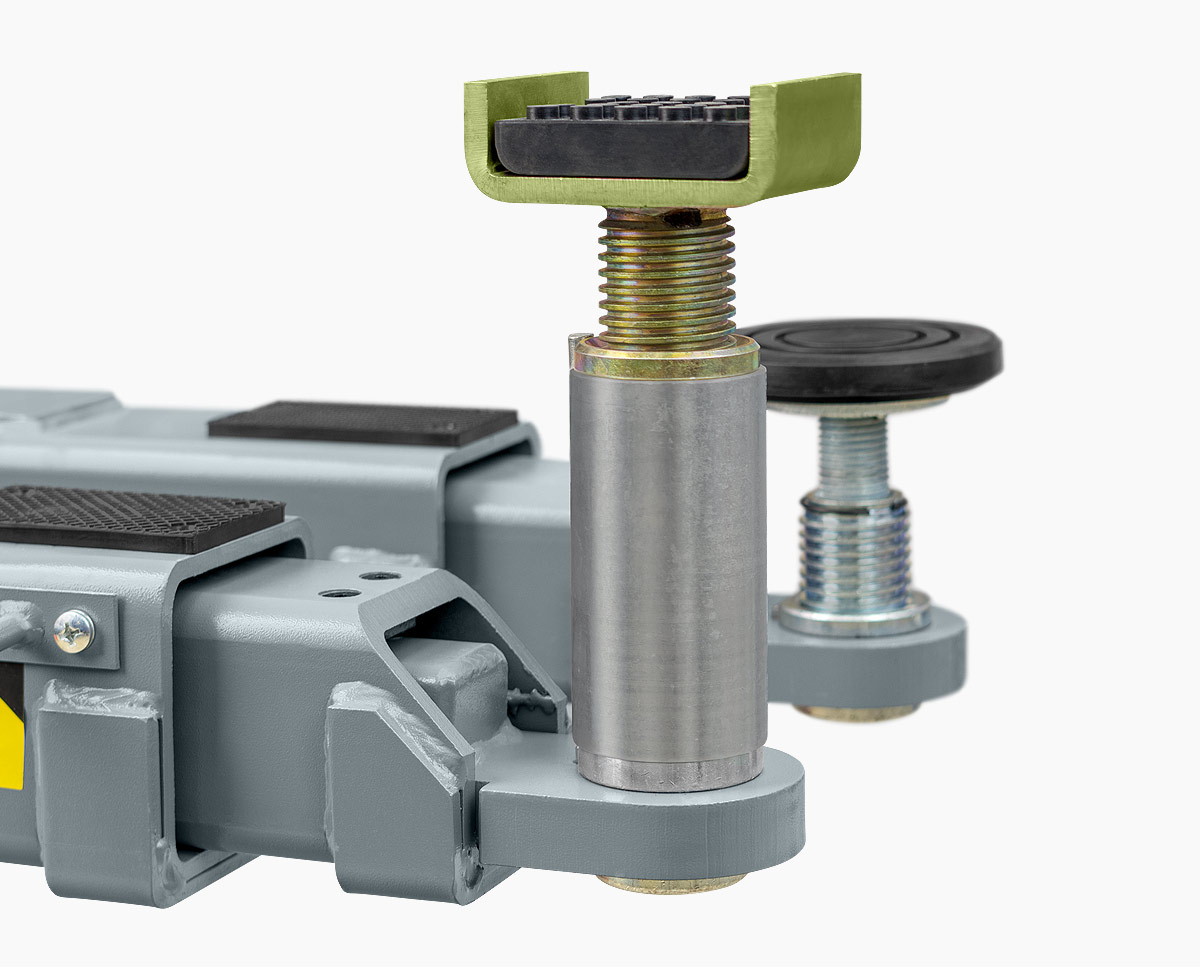

Screw supports for infinitely adjustable vehicle pick-up (from 110 mm from the floor)

Possibility to add optional extensions for frame cars.

Reliable ropes

Lunch elevators use oversized steel cables (9 mm) with a high quality galvanized coating to prevent corrosion.

Enlarged pulleys

The pulleys have an increased diameter and width, which significantly extends the service life of the cables.

Hydraulic system safety

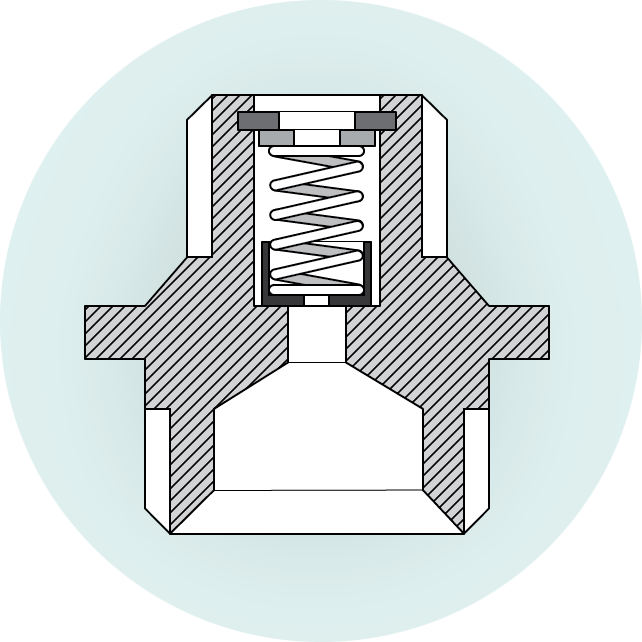

The hydraulic system of the Lunch double rack elevator is equipped with parachute valves, preventing the rapid escape of oil from the cylinders and rapid descent of the vehicle in case of mechanical damage to the hydraulic system of the elevator (except for models (ECO) 240SB).

Protection of elevator components

All electrical wiring is laid in standard internal protective metal boxes (as well as hydraulic wiring), which reliably protect the wiring elements from damage.

European certification

Launch's load capacity is certified to European CE standards (tested under a dynamic load of 115% and static load of 150%) (except ECO models).

The elevators are available in three colors: red / gray / blue;

And also:

- All models of Launch elevators are equipped with a reliable system of stoppers that hold the position of the carriage when working with the car and automatically secure it when lifting.

- In SB models, unlocking is performed by a cable drive. The cable channels for controlling the stoppers are arranged in such a way as to prevent wear and damage to the locking mechanism cables and jamming of the stoppers.

- The hydraulic cylinder sealing and guide collars are a composite design of spacers and seals that have a significantly longer life (instead of one standard collar in alternative hoist versions);

- The hydraulic system of Launch double rack elevator is equipped with parachute valves, preventing the rapid escape of oil from the cylinders and rapid descent of the vehicle in case of mechanical damage to the hydraulic system of the elevator.

- Statutory internal protective boxes for electrical wiring.

- Launch load capacity is certified according to European CE standards (tested under dynamic load 1100px and static 150%) (except for ECO models)

- Calibrated and re-cleaned threaded holes after the painting cycle.

- Geometric conformity to the documentation (accurate manufacturing of all elements, including the dimensions of the synchronization ladder guards, and the appropriate location of the fastening points of the elevator elements)

- Complete set of necessary fasteners for the assembly of the elevator, including a set of anchors and metal spacer plates for the leveling of the racks.

- A complete set of necessary fasteners for the assembly of the elevator, including a set of anchors and metal spacer plates for the leveling of the racks.

- The carriage guide plates are made of high-strength polyamide, which guarantees a long service life. The collapsible design of the carriage greatly simplifies preventive maintenance work on the mechanism or plate replacement (no need to disassemble the elevator and drop the stands)

- Protective cover of the external elements of the hydraulic line

Safety:

Precise assembly and easy maintenance

Options:

- A set of extensions for lifting frame cars (height 60mm / 90mm / 125mm / 140mm)

- P-shaped grips (platforms with sides) for working with frame cars

- Lifting legs in different configurations (2-section 800~1200mm (in ECO 240SB model), reinforced 3-section 600~1105 mm, reinforced extended 2-section 980~1570 mm, reinforced extra long 3-section 950~1800 mm.)

- Document pockets (magnetic or double-sided tape)